Specifications

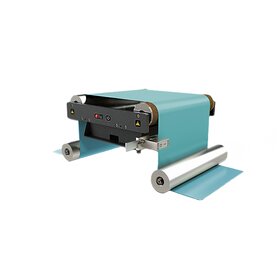

- robust body with high load capacity

- the flange is always custom-made for the customer

- a pneumatically actuated piston opens the mechanical jaws

- always 100% concentric expansion

Pneumatic and pneumatic-mechanical heads are the starting point in applications where the direction of torque action changes during unwinding or winding. These are mainly motorized unwinding stands, where the motor first drives the roll to bring it up to working speed, and later brakes and creates tension in the material. The clamping force of these heads does not depend on the magnitude or direction of the moment, but is constant, induced by the air pressure in the head. The heads are also suitable for high weight and roll unwinding speed applications. They perfectly center the sleeve, thus eliminating roll jumping and vibration. This is a less used model mainly due to the higher price and more frequent maintenance compared to mechanical heads.