Browse our product portfolio | Golpretech

- Pneumatic expanding shafts

- Core chucks

- Safety Chucks

- Bowed and spreading rollers

- Rewinding rollers

- Technical special rollers

- Brakes and clutches

- Tension control systems

- Web guiding systems

- Camera systems for material inspection

- Knives and pneumatic holders

- Manipulators

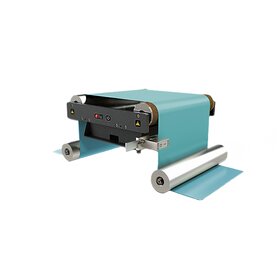

- Machines

- Extraction systems

- FLEXOgraphic printing

- Spare parts for BOBST machines

Tension control systems

Systems for regulating the tension of the running material help to maintain the prescribed tension during the entire rewinding process, reduce the number of material breaks, rejects and minimize losses in production. For systems with open-loop regulation, this is an ultrasonic sensor that detects the diameter of the roll unwinding and controls the unwinding brake based on it. In systems with closed-loop control, strain gauges continuously sense tension in the running material and convert it into an analog signal. This signal is processed by the control unit together with other signals and evaluated by the PID controller. The output can be a signal for the unwinding brake, the coating NIP station, or for the winding motor.