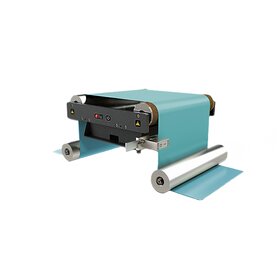

The company therefore decided to install an edge straightening device from RE in front of the winding. The device works as a rotating frame with a sliding drive, a pair of transfer rollers and a sensor for sensing the edge position. In this case, the ultrasonic sensor (for the transparent film) proportionally scans the edge of the material and always adjusts the material to the required position by rotating the frame.

The installation took place after consultation with a Golpretech technician and a location proposal. In this case, the position of one guide roller was changed to guarantee a 90° entry and exit path of the material from the device.

The ultrasonic sensor is installed on a square aluminum bracket, which allows it to be moved if the width of the processed material changes. For other materials, infrared and camera-based sensors are also available that can sense contrast or follow a preprinted line.

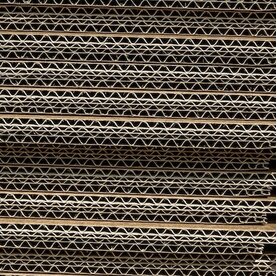

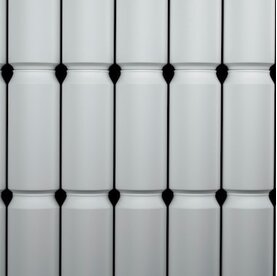

Using the installed equipment, it was possible to significantly improve the quality of the wound roll. As a test, a previously wound roll was rewound for testing. In the picture you can see the roll that was wound without using the system. We placed this roll on the reel once again and wound it using the edge straightener.