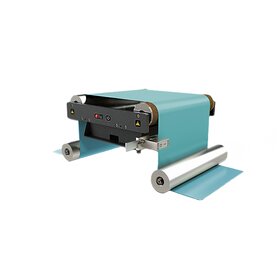

In Slovakia, they had a problem with uneven material pulling, with the cutting speed of the machine and with unevenly wound winding rolls.

After a personal visit and analysis of the problem, we proposed an effective solution in three steps:

1. The original unwinding unit of the machine was equipped with a pneumatic friction brake to control the unwinding torque without feedback. We replaced this brake with an asynchronous motor with a gearbox controlled by a frequency converter.

2. The original cutting unit of the machine was driven by an asynchronous gear motor. The control was out of sync with the other actuators of the machine. We replaced the drive control with a frequency converter with synchronization with the winding and unwinding converter.

3. We synchronized the drive of the winding unit with the other action parts of the machine. The winding tension is measured and controlled from the control unit. We have installed a modern touch 7" display on the machine control for setting and checking parameters, displaying alarms and machine status.