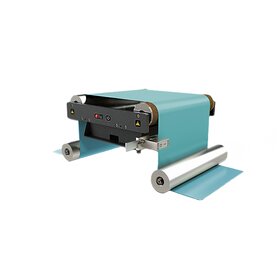

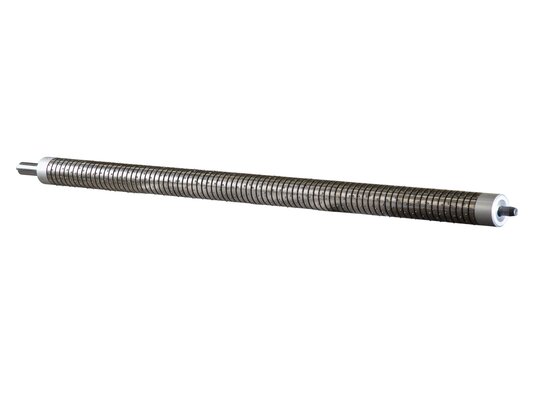

Special shaft for differential winding

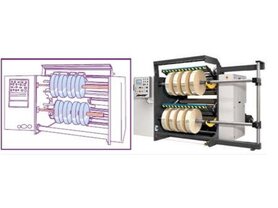

Special shafts for differential winding are the ideal solution for multiple and independent winding of cylinders on the same shaft, as each of them needs the correct tension of the belt.

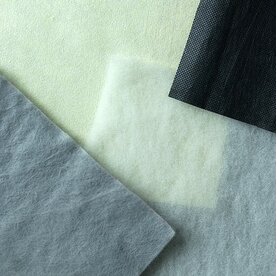

During the rewinding process, multiple rolls obtained after the process of cutting plastic film, paper or any other material, it is common for them to have important differences in thickness and, as a result, also differences in belt tension. To solve this problem, these special shafts provide a different control of the rollers blocking the core of each roller on one or more friction rings to obtain a precise rewind and even tension of the belt of each roller.

These special shafts are equipped with nickel-plated steel friction rings with a wide bearing surface and expansion rollers, which guarantee a wider gripping surface compared to rings. This new technology ensures:

- wider bearing area

- no damage to the core of the sleeve/coil

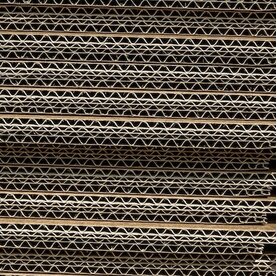

- use with both cardboard and plastic cores

- the smallest dimension