Specifications

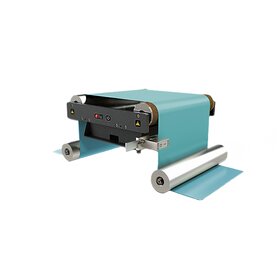

- suitable for coreless winding or for winding on thin cores

- knurled clamping bars for torque transmission

- ideal for foam materials and fiberglass

Shafts with clamping bars around the entire circumference and full width are mainly used for coreless winding of rolls, or for winding on very thin cores where segments or belts could deform the core. After inflation, the wide segments extend, thus increasing the entire circumference of the shaft. These shafts are suitable for high thrust applications and are often seen in a flanged design. They are made of a robust steel body, wide aluminum slats and are mounted as standard in a one-sided woven design.