Detailed specifications

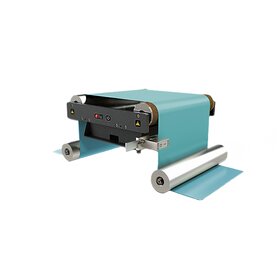

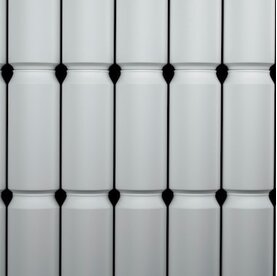

For the high demands of the flexographic industry, we offer, in cooperation with the Pamarco company, a range of anilox cylinders or anilox sleeves that meet the strictest criteria.

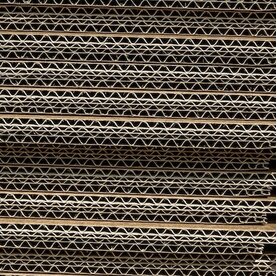

The surface of all cylinders consists of a durable ceramic layer, resistant to scratching when in contact with steel or a scraper knife. Another bonus of the ceramic surface is the ability to resist corrosion. Advanced laser technology enables very detailed and clean engraving of anilox cells. Thanks to this, our anilox cylinders transfer the ink to the printing plate with maximum precision with every print.