Specifications

- accurate detection of material stress

- perfect fabric tension

- a wide range of load cells with tensometric technology guarantees accuracy and reliability for all kinds of applications

- available for loads from 50 N to 30000 N

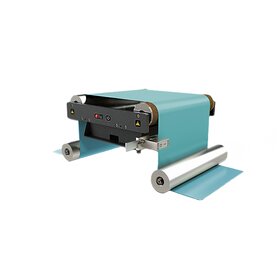

Accurate recognition of material tension is the first step to achieving perfect fabric tension. Our wide range of load cells with strain gauge technology guarantees accuracy and reliability for all kinds of applications.

In addition to flange, shaft and basic sensors, we also offer sensing rollers, cantilever, compression and tension sensors. They are available for loads from 50 N to 30000 N.