The original manufacturer of tilting bearings could no longer be traced, so we lacked any drawing documentation in this application. We visited the customer and created technical documentation. Since it was necessary to adapt to the existing mounting dimensions and dimensions of the clamping shafts, we had to make mounting adapters. An adaptation flange was made for the tilting bearings for mounting the existing brake.

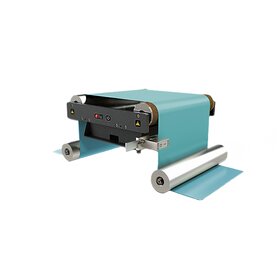

According to the client's requirements, we specified a suitable type of tilting bearings. These were side shift bearings for fine alignment of the roll unwinding. A 40 x 40 mm square bearing is turned 45 degrees, which allows the shaft pin to fit easily when handling the crane. We chose a model with replaceable jaws, so in the future maintenance will be simple and quick. The bearings are robust and can handle a maximum load of up to 1600 kg and 1000 revolutions per minute.