Realization:

December 2017

Location:

Slovakia

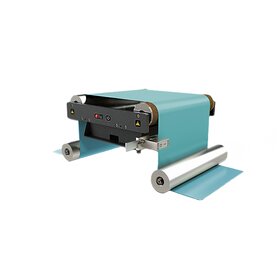

To solve the problem, we designed a complete unwinding station for the customer, which consists of fixedly installed opening tilt bearings with an installed brake and an ultra-light aluminum shaft that has only 3 belts and a hollow profile to reduce weight. Handling the shaft, which weighs only 16 kg, is easy and can easily be handled by one person. This increased the speed and comfort of changing the role and increased the overall productivity.